What product types are included in resistor wiring?

What Product Types are Included in Resistor Wiring?

I. Introduction

A. Definition of Resistor Wiring

Resistor wiring refers to the integration of resistors into electrical circuits to control current flow, divide voltages, and protect sensitive components. Resistors are fundamental components in electronic devices, playing a crucial role in ensuring that circuits function correctly and efficiently.

B. Importance of Resistor Wiring in Electrical Circuits

In electrical engineering, resistors are essential for managing the flow of electricity. They help to prevent damage to components by limiting current, enable voltage division for signal processing, and are integral in feedback loops for amplifiers. Without resistors, circuits would be prone to overloads, leading to failures and malfunctions.

C. Overview of the Article

This article will explore the various product types included in resistor wiring, detailing the different types of resistors, their applications, and considerations for selection and installation. By understanding these components, readers can make informed decisions when designing or repairing electrical circuits.

II. Understanding Resistors

A. What is a Resistor?

1. Function and Purpose

A resistor is a passive electrical component that resists the flow of electric current. Its primary function is to limit current, divide voltages, and dissipate energy in the form of heat. Resistors are characterized by their resistance value, measured in ohms (Ω), which determines how much they resist current flow.

2. Basic Principles of Resistance

The principle of resistance is governed by Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. This relationship is expressed as V = I × R.

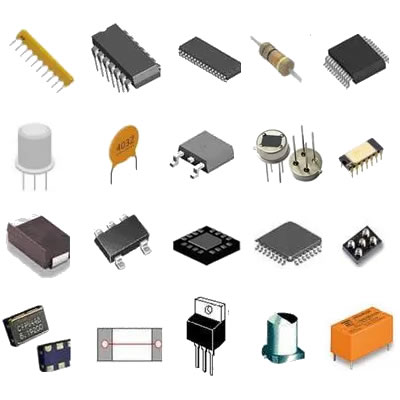

B. Types of Resistors

1. Fixed Resistors

Fixed resistors have a constant resistance value and are widely used in various applications. They are available in several materials and configurations, each suited for specific tasks.

2. Variable Resistors

Variable resistors allow for adjustable resistance values, making them ideal for applications where fine-tuning is necessary, such as in volume controls and dimmer switches.

3. Specialty Resistors

Specialty resistors are designed for specific applications, such as temperature sensing or light detection. These resistors have unique properties that make them suitable for specialized tasks.

III. Product Types in Resistor Wiring

A. Fixed Resistors

1. Carbon Composition Resistors

Carbon composition resistors are made from a mixture of carbon particles and a binding resin. They are known for their high energy absorption and ability to withstand high temperatures, making them suitable for applications where reliability is critical.

2. Metal Film Resistors

Metal film resistors are constructed using a thin layer of metal deposited on a ceramic substrate. They offer high precision and stability, making them ideal for applications requiring accurate resistance values.

3. Wirewound Resistors

Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core. They can handle high power levels and are often used in power applications, such as power supplies and amplifiers.

4. Thick and Thin Film Resistors

Thick film resistors are made by applying a thick layer of resistive material to a substrate, while thin film resistors use a much thinner layer. Thin film resistors offer better precision and stability, while thick film resistors are more cost-effective for general applications.

B. Variable Resistors

1. Potentiometers

Potentiometers are three-terminal devices that allow for adjustable resistance. They are commonly used in volume controls, tuning circuits, and other applications where variable resistance is needed.

2. Rheostats

Rheostats are similar to potentiometers but are typically used to control higher currents. They are often found in applications such as motor speed controls and lighting dimmers.

3. Trimmers

Trimmers are small variable resistors used for fine-tuning circuits. They are often used in calibration and adjustment applications, allowing for precise control over resistance values.

C. Specialty Resistors

1. Thermistors

Thermistors are temperature-sensitive resistors that change resistance with temperature variations. They are commonly used in temperature sensing and control applications, such as in thermostats and temperature monitoring systems.

2. Photoresistors

Photoresistors, or light-dependent resistors (LDRs), change resistance based on light exposure. They are widely used in light-sensing applications, such as automatic lighting systems and camera exposure controls.

3. Varistors

Varistors are voltage-dependent resistors that protect circuits from voltage spikes. They are commonly used in surge protection devices to safeguard sensitive electronics from transient voltage surges.

4. Resistor Networks and Arrays

Resistor networks and arrays consist of multiple resistors packaged together. They are used to save space on printed circuit boards (PCBs) and simplify circuit design by providing multiple resistance values in a single component.

IV. Applications of Resistor Wiring

A. Consumer Electronics

Resistor wiring is prevalent in consumer electronics, including televisions, radios, and smartphones. They help regulate current and voltage levels, ensuring devices operate safely and efficiently.

B. Industrial Equipment

In industrial settings, resistors are used in machinery and control systems to manage power levels and protect sensitive components from overloads.

C. Automotive Applications

Automobiles utilize resistors in various systems, including lighting, engine control units, and sensor circuits, to ensure proper functionality and safety.

D. Telecommunications

In telecommunications, resistors are essential for signal processing and conditioning, helping to maintain signal integrity over long distances.

E. Medical Devices

Medical devices rely on resistors for accurate measurements and control, ensuring patient safety and device reliability in critical applications.

V. Factors to Consider When Choosing Resistor Wiring Products

A. Resistance Value

The resistance value is a critical factor in selecting resistors, as it determines how much current will flow through the circuit. It is essential to choose a resistor with the appropriate resistance value for the specific application.

B. Power Rating

The power rating indicates how much power a resistor can handle without overheating. Selecting a resistor with an adequate power rating is crucial to prevent damage and ensure reliable operation.

C. Tolerance

Tolerance refers to the allowable variation in resistance value. Choosing resistors with appropriate tolerance levels is essential for applications requiring precise resistance values.

D. Temperature Coefficient

The temperature coefficient indicates how much a resistor's resistance changes with temperature. Selecting resistors with suitable temperature coefficients is vital for applications exposed to varying temperatures.

E. Size and Form Factor

The physical size and form factor of resistors can impact circuit design and layout. It is essential to consider these factors to ensure compatibility with the intended application.

VI. Installation and Wiring Techniques

A. Soldering Techniques

Proper soldering techniques are crucial for ensuring reliable connections in resistor wiring. Techniques such as using the right solder type, maintaining appropriate temperatures, and ensuring clean surfaces can significantly impact the quality of the connection.

B. PCB Mounting

When mounting resistors on printed circuit boards (PCBs), it is essential to follow best practices for placement and orientation to ensure optimal performance and reliability.

C. Wiring in Series and Parallel Configurations

Understanding how to wire resistors in series and parallel configurations is vital for achieving desired resistance values and circuit behavior. Series wiring increases total resistance, while parallel wiring decreases it.

D. Safety Considerations

Safety is paramount when working with resistors and electrical circuits. Proper insulation, heat management, and adherence to electrical standards can help prevent accidents and ensure safe operation.

VII. Conclusion

A. Recap of Resistor Wiring Product Types

In summary, resistor wiring encompasses a variety of product types, including fixed, variable, and specialty resistors. Each type serves specific functions and applications, making them essential components in electrical circuits.

B. Importance of Selecting the Right Resistor

Choosing the right resistor is critical for ensuring circuit functionality, reliability, and safety. Factors such as resistance value, power rating, and tolerance must be carefully considered to achieve optimal performance.

C. Future Trends in Resistor Technology

As technology advances, the demand for more efficient and compact resistors continues to grow. Innovations in materials and manufacturing processes are likely to lead to the development of new resistor types that offer improved performance and reliability.

VIII. References

A. Suggested Reading

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Electronic Principles" by Albert Malvino and David Bates

B. Industry Standards and Guidelines

- International Electrotechnical Commission (IEC) standards

- Institute of Electrical and Electronics Engineers (IEEE) guidelines

C. Manufacturer Resources

- Resistor manufacturers' websites for product specifications and datasheets

- Online electronics component distributors for purchasing options

By understanding the various product types included in resistor wiring, their applications, and installation techniques, readers can enhance their knowledge and skills in electrical engineering and circuit design.