What are the product features of varistor?

What are the Product Features of Varistor?

I. Introduction

A. Definition of Varistor

A varistor, or voltage-dependent resistor, is a semiconductor device that exhibits a non-linear resistance characteristic, which changes with the applied voltage. This unique property allows varistors to protect electrical circuits from voltage spikes and transients, making them essential components in various electronic applications.

B. Importance of Varistors in Electrical and Electronic Applications

Varistors play a critical role in safeguarding sensitive electronic equipment from voltage surges caused by lightning strikes, power line disturbances, and other transient events. By clamping excessive voltage levels, they help prevent damage to components, ensuring the longevity and reliability of electronic systems.

C. Overview of the Article Structure

This article will delve into the basic principles of varistors, explore their key product features, discuss their applications, highlight their advantages and limitations, and conclude with insights into future trends in varistor technology.

II. Basic Principles of Varistors

A. Explanation of Voltage-Dependent Resistors

Varistors are classified as voltage-dependent resistors because their resistance decreases as the voltage across them increases. This non-linear behavior allows them to absorb and dissipate energy during voltage spikes, effectively protecting downstream components.

1. Non-linear Resistance Characteristics

The resistance of a varistor is not constant; it varies with the applied voltage. At low voltages, the varistor presents high resistance, allowing normal current flow. However, when a voltage spike occurs, the resistance drops significantly, allowing the varistor to conduct excess current and clamp the voltage to a safer level.

2. Clamping Voltage and Energy Absorption

The clamping voltage is the maximum voltage that the varistor allows to pass through before it begins to conduct heavily. This feature is crucial for protecting sensitive components. Additionally, varistors have a specified energy absorption capacity, which indicates how much energy they can safely dissipate during a surge event.

1. Metal Oxide Varistors (MOVs)

MOVs are the most common type of varistor, made from a ceramic material that contains zinc oxide. They are widely used in surge protection applications due to their high energy absorption capacity and fast response times.

2. Silicon Carbide Varistors (SiC)

SiC varistors are known for their high-temperature stability and superior performance in harsh environments. They are often used in industrial applications where reliability is paramount.

3. Other Varistor Types

Other types of varistors include polymeric varistors and gas discharge tubes, each with unique characteristics suited for specific applications.

III. Key Product Features of Varistors

1. Definition and Importance

The voltage rating of a varistor indicates the maximum continuous voltage it can withstand without conducting. Selecting a varistor with an appropriate voltage rating is crucial to ensure it operates effectively within the intended application.

2. Selection Criteria

When choosing a varistor, it is essential to consider the operating voltage of the circuit and any potential voltage transients that may occur.

1. Explanation of Energy Rating

The energy absorption capacity of a varistor is typically expressed in joules (J) and indicates the amount of energy it can absorb during a surge event without failing.

2. Impact on Performance and Reliability

A higher energy rating generally translates to better performance and reliability, as it allows the varistor to handle more significant surges without degradation.

1. Definition and Measurement

Response time refers to the speed at which a varistor reacts to a voltage spike. It is typically measured in nanoseconds.

2. Importance in Surge Protection

A fast response time is critical for effective surge protection, as it ensures that the varistor can clamp the voltage before it reaches sensitive components.

1. Definition and Role in Circuit Protection

Clamping voltage is the voltage level at which the varistor begins to conduct significantly. It is a key parameter in determining how well the varistor can protect downstream components.

2. Relationship with Operating Voltage

The clamping voltage should be higher than the normal operating voltage of the circuit but low enough to protect sensitive components from damage.

1. Explanation of Temperature Effects

The temperature coefficient of a varistor indicates how its resistance changes with temperature. A positive temperature coefficient means resistance increases with temperature, while a negative coefficient indicates the opposite.

2. Importance in Varistor Selection

Understanding the temperature coefficient is essential for selecting a varistor that will perform reliably in varying environmental conditions.

1. Definition and Measurement

The surge current rating indicates the maximum current the varistor can handle during a surge event without failing. It is typically measured in amperes (A).

2. Implications for Circuit Design

Designers must ensure that the surge current rating of the varistor exceeds the expected surge currents in the application to prevent failure.

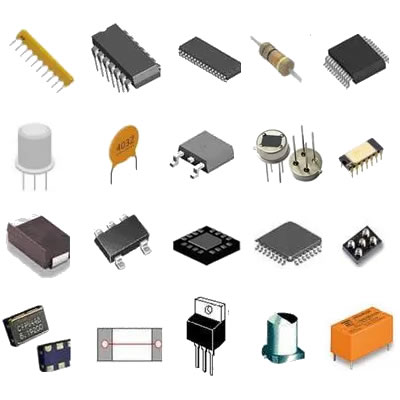

1. Variations in Size and Shape

Varistors come in various sizes and shapes, including disc, rectangular, and surface-mount configurations.

2. Impact on Application and Installation

The physical size and form factor can influence the choice of varistor based on space constraints and installation requirements in the circuit.

1. Factors Affecting Longevity

The reliability and lifespan of a varistor can be affected by factors such as operating conditions, frequency of surge events, and environmental factors.

2. Importance of Quality Standards

Choosing varistors that meet industry quality standards can help ensure long-term reliability and performance.

IV. Applications of Varistors

A. Use in Power Supply Circuits

Varistors are commonly used in power supply circuits to protect against voltage spikes that can occur during switching operations or power outages.

B. Protection in Communication Systems

In communication systems, varistors help protect sensitive equipment from transients caused by lightning strikes or electrical noise.

C. Applications in Consumer Electronics

Varistors are widely used in consumer electronics, such as televisions and computers, to safeguard against voltage surges that could damage internal components.

D. Industrial Applications

In industrial settings, varistors protect machinery and control systems from voltage spikes, ensuring operational continuity and safety.

E. Automotive Applications

Varistors are increasingly used in automotive applications to protect electronic control units (ECUs) from voltage transients caused by engine operation or external factors.

V. Advantages of Using Varistors

A. Cost-Effectiveness

Varistors are relatively inexpensive compared to other surge protection devices, making them a cost-effective solution for many applications.

B. Versatility in Applications

Their ability to handle a wide range of voltages and currents makes varistors suitable for various applications across different industries.

C. Enhanced Safety and Protection

By clamping voltage spikes, varistors enhance the safety and protection of electronic devices, reducing the risk of damage and failure.

D. Low Maintenance Requirements

Varistors typically require minimal maintenance, making them a convenient choice for long-term applications.

VI. Limitations and Considerations

A. Potential for Degradation Over Time

Varistors can degrade over time, especially after repeated surge events, which may lead to reduced performance and eventual failure.

B. Temperature Sensitivity

Varistors can be sensitive to temperature changes, which may affect their performance and reliability in extreme conditions.

C. Selection Challenges

Choosing the right varistor for a specific application can be challenging due to the variety of types, ratings, and specifications available.

D. Alternatives to Varistors

While varistors are effective for surge protection, alternatives such as transient voltage suppressors (TVS) and gas discharge tubes may be more suitable for certain applications.

VII. Conclusion

A. Summary of Key Features and Benefits

Varistors are essential components in protecting electronic circuits from voltage spikes. Their key features, including voltage rating, energy absorption capacity, response time, and clamping voltage, make them versatile and effective in various applications.

B. Importance of Proper Selection and Application

Selecting the right varistor for a specific application is crucial to ensure optimal performance and protection. Understanding the key features and specifications can help engineers make informed decisions.

C. Future Trends in Varistor Technology

As technology advances, we can expect to see improvements in varistor materials and designs, leading to enhanced performance, reliability, and miniaturization for modern electronic applications.

VIII. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Electronic Materials

B. Industry Standards and Guidelines

- IEC 61000-4-5: Surge Immunity Test

- UL 1449: Standard for Surge Protective Devices

C. Manufacturer Specifications and Datasheets

- Manufacturer datasheets for specific varistor models

- Technical documentation from leading varistor manufacturers

This comprehensive overview of varistors highlights their critical role in electrical and electronic applications, emphasizing the importance of understanding their features and selecting the right type for specific needs. As technology continues to evolve, varistors will remain a vital component in ensuring the safety and reliability of electronic systems.